Vibro-Consult AG

Case-Studies

Bearing Alignment Problem (Switzerland)

Initial situation

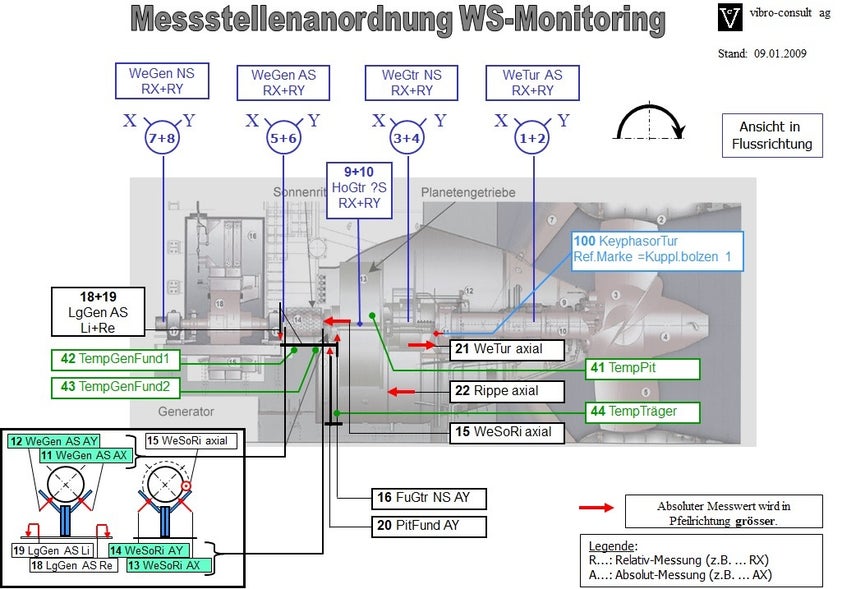

In a bulb turbine (generator-gearbox-turbine design), there were inexplicable vibration phenomena at the certain guide bearings. After several hours of operation, one bearing was even found to be totally damaged. The task was to find out what was the cause of this problem.